AMS ASME ASTM ye inconel625 alloy navigator

AMS ASME ASTM ye inconel625 alloy navigator,

625 Alloy,Inconel 625 Bars ,Inconel 625 Tsvimbo,Inconel 625 sheet ,Inconel 625 plate,Inconel 625 strip,Inconel 625 coil,

Mazita Ekutengesa Anowanikwa: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

Inconel Alloy 625 is non-magnetic, corrosion and oxidation resistant, nickel-chromium alloy.Kusimba kwepamusoro kweInconel 625 mhedzisiro yekuomesa musanganiswa wemolybdenum uye niobium pane nickel chromium base yealloy.Inconel 625 ine kuramba kwakakura kune dzakasiyana siyana dzakanyanya kuomarara nharaunda dzinosanganisira yakakwirira-tembiricha mhedzisiro senge oxidation uye carburization.Simba rayo rakatanhamara uye kuomarara kwetembiricha kubva patembiricha ye cryogenic kusvika patembiricha yakakwira kusvika 2000 ° F (1093° C) inotorwa zvakanyanya kubva kune yakasimba mhinduro mhedzisiro yesimbi inopikisa Columbium uye molybdenum mune nickel-chromium matrix.

Inconel 625 Chemical Kuumbwa

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Max. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 Zvenyama Zvivakwa

| Density | 8.4 g/cm³ |

| Melting point | 1290-1350 ℃

|

Inconel 625 Typical Mechanical Properties

| Status | Kusimba simba Rm N/mm² | Goho simba Rp 0. 2N/mm² | Elongation Se % | Brinell kuoma HB |

| Solution kurapwa | 827 | 414 | 30 | ≤220 |

Inconel 625 Mitemo uye Matsanangudzo

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE M3R, NACE M3

UNS N06625, Werkstoff 2.4856

| Waya | Sheet | Strip | Rod | Pipe | |

| AMS 5599, AMS 5666,AMS 5837, AMS 5979,ASTM B443 | ASTM B443 | AMS 5599, AMS 5979,ASTM B443 | ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Seamless Pipe | Welded Pipe |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Inconel 625 Inowanikwa Zvigadzirwa muSekonic Metals

Inconel 625 Bars & Tsvimbo

Round bars/Flat bars/Hex bars, Saizi Kubva 8.0mm-320mm, Inoshandiswa kumabhaudhi, mabhaudhi uye zvimwe zvakasara

Inconel 625 welding waya

Supply in welding wire uye spring wire mune coil fomu uye kucheka kureba.

Inconel 625 sheet & plate

Upamhi hunosvika 1500mm uye kureba kusvika 6000mm, Hukobvu kubva 0.1mm kusvika 100mm.

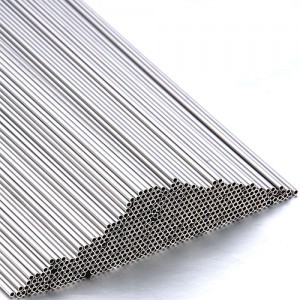

Inconel 625 isina musono chubhu & Welded pombi

Mayero saizi uye yakasarudzika dimension inogona kugadzirwa nesu nekushivirira kudiki

Inconel 625 strip & coil

Yakapfava mamiriro uye yakaoma mamiriro ane AB inopenya nzvimbo, yakafara kusvika 1000mm

Inconel 625 Fasteners

Alloy 625 tinogona kupa mabhaudhi, Nzungu uye zvimwe zvinosungirira sezvinodiwa nevatengi

Inconel 625 Features :

1.High creep-rupture simba

2.Oxidation inoshingirira kusvika 1800°F

3.Good kuneta kuramba

4.Excellent weldability

5.Kunyanya kupikisa kune chloride pitting uye crevice corrosion

6.Immune kune chloride ion stress corrosion cracking

7.Kurwisana nemvura yegungwa pasi pezvinhu zvose zvinoyerera uye zvakadzika uye pasi pekusvibiswa

Inconel 625 Munda wekushandisa:

•Ndege ducting masisitimu

•Jet injini exhaust systems

•Engine thrust-reverser masisitimu

•Mabhero uye majoini ekuwedzera

•Turbine shroud zvindori

•Flare stacks

•Zvikamu zvemvura yegungwa

•Chemical process midziyo inobata yakasanganiswa asidhi zvese oxidizing uye kuderedza.

Kambani Yedu Zvigadzirwa Mafomu

Mabhawa & Matanda

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless Tube & Welded Tube

Nickel/ Titanium Alloy machubhu, U-bend / kupisa kwekuchinjana chubhu

Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Sheet & Plates

Hastelloy/Inconel/Incoloy/Cobalt/Tianium

Strip & Foil

Hastelloy/Inconel/ invar/ soft magnetic Alloys ect

High Temperature Springs

Inconel 718/Inconel x750/ Nimonic 80A

Wire & Welding

Cobalt Alloy waya, nickel alloy waya, Tianium Alloy waya

Special Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Mafuta Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Nickel Based Alloys

Welding Materials

Cobalt Based Alloys

Special Stainless Steels

Precision Alloys

Titanium Alloys

Unoda Kudzidza Zvakawanda kana kuwana quote?

Pinda muBata

Chii chinonzi 625 alloy yakagadzirwa?Nickel - yakavakirwa alloy ine yakakwirira Ni - Cr - Mo.

Kemikari yakagadzirwa neAlloy 625: Chromium (Cr)20.0-23.0, Iron (Fe)< 5.0, (Al) & lt;0.4, Silicon (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni)258, sulfur (S)< 0.015, Cobalt (Co)< 1.0,(Mo)8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015,(Nb) 3.15-4.15, Carbon (C)< 0.01.

625 Alloy inoratidzira yakanakisa oxidation uye corrosion kuramba, kusimba kwakanyanya uye kuoma, kwakanyanya kuneta kuramba, yakakwirira kuumbwa, uye yakanakisa weldability.Inogona kuchengetedza simba rayo uye kusimba chero kupi zvako kubva kune yakaderera tembiricha kusvika 2000 ° F.Nekuda kwekukurumidza kuomeswa kwealloy 625, kuwanda kwekutonhora kuumbwa kungangoda kuvharirwa mukati mekutonhora kuumba maitiro.Iyo alloy inowanzoshandiswa mumajini ejet uye mamwe maapplication emuchadenga.