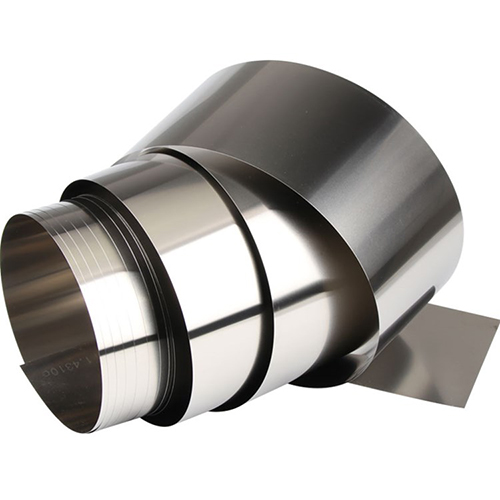

Titanium Strip uye Foil

• Tittanium Strip uye Foil Materials:Yakachena Titanium (CP) uye Titanium alloy foil,Grade1, Grade 2, Grade 5, Grade 5, Grade 7 neGrade 9

• Mafomu: Mutsara mumwechete, mune coil, kana pane spool.Slitting service iripo

• Dimension:Ukobvu: ≥0.01mm : 20~1000mm, Kureba: Sechikumbiro

• Conditions:Kutonhora kwakakungurutswa(Y)~Hot rolled(R)~Annealed (M)~Solid Status

• Maitiro:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 nezvimwe.

• Applications:Magetsi, makemikari, wachi, magirazi, zvishongo, zvemitambo, michina, plating midziyo, midziyo yezvakatipoteredza, gorofu uye maindasitiri ekugadzira machina.

| Titanium Alloys Material Common Name | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Titanium Strip uye Foil:Isu tinonyanya kupa yakachena titanium Strip yeGr1, Gr2, Gr4 mamakisi;Kune titanium alloy Foil, Isu tinonyanya kupa Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 uye mamwe mamakisi,Iwo anogadzirwa pahwaro hwetitanium ndiro pamwe nekumwe kutonhora kutenderera;nzira yekugadzira titanium sheet yakanyanya kuoma.Iyo deformation control yakanyanya kusimba mukuita rolling.Iyo inogona kutemwa muhukuru hwakasiyana maererano nezvinodiwa nemutengi, kupfupisa zvakanyanya nguva yekuendesa.

♦ Titanium Strip Chemical composition ♦

| Giredhi | Kemikari yakagadzirwa, uremu muzana (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Zvimwe Zvinhu Max.chimwe nechimwe | Zvimwe Zvinhu Max.zvachose | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy StripZvinhu zvemuviri♦

| Giredhi | Zvinhu zvemuviri | |||||||

| Kusimba simba Min | Goho simbaZvishoma (0.2%, offset) | Elongation mu4D Zvishoma (%) | Kuderedzwa kweNzvimbo Zvishoma (%) | Bend Test (Radius yeMandrel) | ||||

| ksi | MPa | ksi | MPa | <1.8mm In makobvu | 1.8-4.8mm Mukukora | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

•Giredhi 1: Yakachena Titanium, yakaderera simba uye yakakwira ductility.

•Giredhi 2: Iyo yakachena titanium inonyanya kushandiswa.Kubatanidzwa kwakanakisisa kwesimba

•Giredhi 3: Yakakwirira simba Titanium, inoshandiswa kuMatrix-maplateti mugoko uye chubhu yekupisa inotsinhanisa

•Giredhi 5: Iyo yakanyanya kugadzirwa titanium alloy.Simba rakakwirira zvakanyanyisa.kupisa kwakanyanya.

•Giredhi 7: Superior corrosion kuramba mukudzikisa uye oxidizing nharaunda.

•Giredhi 9: Yakanyanya kusimba simba uye ngura kuramba.

•Giredhi 12: Zvirinani kupisa kupisa pane yakachena Titanium.Zvikumbiro seGrade 7 uye Grade 11.

•Giredhi 23: Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy yekuvhiya kuisa kuiswa.