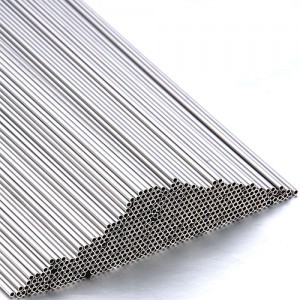

Welding Wire ERNiFeCr-1 Incoloy 825 waya

ErNiFeCr-1 Incoloy 825, UNSN08825 Welding Wire

♦Welding Material Zita: Nickel welding Wire, Incoloy 825, ErNiFeCr-1

♦MOQ: 15kg

♦Fomu: MIG (15kgs/spool), TIG (5kgs/bhokisi)

♦Saizi: dhayamita 0.01mm-8.0mm

♦Saizi Yakajairwa: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

♦Maitiro: Inopindirana neChitupa AWS A5.14 ASME SFA A5.14

ERNiFeCr-1inoshandiswa kuTIG, MIG uye SAW welding ye nickelchromium-molybdenum-copper alloys.Izvi zvinogona zvakare kushandiswa kufukidza machira panodiwa makemikari akafanana

| C | Cr | Ni+Co | Si | Mn | P | S | Cu | Al | Mo | Ti | Fe |

| ≤0.05 | 19.5-23.5 | 38.0-46.0 | ≤0.5 | ≤1.0 | ≤0.03 | ≤0.03 | 1.5-3.0 | ≤0.2 | 2.5-3.5 | 0.6-1.2 | ≥22 |

| Condition | Tensile Simba MPa (ksi) | Yield Strength MPa (ksi) | Elongation% |

| AWS reauirement | 550(80) | Hazvina kutaurwa | Hazvina kutaurwa |

| Yakajairika mhinduro sewelded | 550(80) | - | 25 |

SeiERNiFeCr-1?

1. Inoshandiswa pakugadzira nickel-chromium-molybdenum-copper alloys.

2.Zvakare zvinogona kushandiswa kufukidza machira apo yakafanana kemikari inoumbwa inodiwa

3. Inoshandiswa kugadzira nickel-iron-chromium-molybdenum-copper alloy (ASTM B 423 ine UNS nhamba N08825) kwayo pachayo uchishandisa GTAW uye GMAW maitiro.