Hastelloy C276 ine ERNiCrMo-4 welding waya

Hastelloy C276 ine ERNiCrMo-4 welding waya,

ERNiCrMo-4 (UNS N10276) welding, ERNiCrMo-4 Goridhe welding waya, Hastelloy C276 welding waya, Hastelloy C276 ine ERNiCrMo-4 welding waya,

ErNiCrMo-4 Hastelloy C276(UNS 10276)Welding Wire

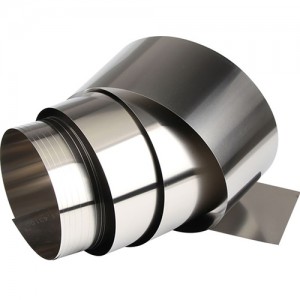

♦Welding Material Zita: Nickel welding Wire, ErNiCrMo-4, Hastelloy C276 Welding Wire

♦MOQ: 15kg

♦ Fomu:MIG(15kgs/spool), TIG(5kgs/bhokisi)

♦Saizi: dhayamita 0.01mm-8.0mm

♦ Saizi Yakafanana: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

♦Maitiro: Inopindirana neChitupa AWS A5.14 ASME SFA A5.14

Bata Isu Kuti Udzidze Zvakawanda!

ErNiCrMo-4 inoshandiswa kugadzira simbi yeHastelloy C276, Nickel base alloy uye zvimwe zvinhu, Nickel alloy kusimbi kana simbi isina tsvina, inoshandiswawo kugadzira Nickel CrMo alloy composite layer pasimbi.Main welding materials emakemikari akafanana pamwe chete nezvinhu zvakasiyana zve nickel base alloys. , simbi uye simbi isina tsvina.Iyi alloy inogona kushandiswawo kuvhara simbi ine nickel-chrome-molybdenum weld metal.Iyo yakakwira molybdenum yemukati inopa kuramba kwakakura kushushikana nekupwanya kwegora, gomba uye crevice corrosion.

ERNiCrMo-4 Chemical Kuumbwa

| C | Cr | Ni | Si | Mn | P | S | Cu | Fe | V | W | Mo | Co |

| ≤0.02 | 14.5-16.5 | Ba | ≤0.08 | ≤1.0 | ≤0.04 | ≤0.03 | ≤0.5 | 4.0-7.0 | ≤0.35 | 3.0-4.0 | 15.0-17.0 | ≤2.5 |

ERNiCrMo-4 Typical Welding Parameter

| Diameter | Process | Volt | Amps | Shielding Gasi | |

| In | mm | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | Spray Transfer100% Argon |

| 0.045 | 1.2 | GMAW | 28-32 | 180-220 | |

| 1/16 | 1.6 | GMAW | 29-33 | 200-250 | |

| 1/16 | 1.6 | GMAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | GMAW | 15-20 | 120-175 | 100% Argon |

| 1/8 | 3.2 | GMAW | 15-20 | 150-220 | 100% Argon |

ERNiCrMo-4 Mechanical Properties

| Condition | Tensile Simba MPa (ksi) | Yield Strength MPa (ksi) | Elongation% |

| AWS reauirement | 690(100) | Hazvina kutaurwa | Hazvina kutaurwa |

| Yakajairika mhinduro sewelded | 730(106) | 540(79) | 39 |

KUDZIVIRIRA GESI:

MIG:75% Ar / 25% Iye

TIG:100% Ar

Sei ERNiCrMo-4 ?

Iyo alloy inopesana neasidhi uye acid vapor corrosion.Nekuda kwehuwandu hwayo hwemolybdenum, ine kurwisa kwakasimba kumanikidziro ekuora, pitting uye cavitation corrosion.

ERNiCrMo-4 Application field:

Inoshandiswa zvakanyanya mumakemikari mudziyo mapaipi, pombi mavharuvhu, simba indasitiri flue gasi desulfurization uye welding -196 ℃ kushandiswa kwe9% Ni simbi.

Welding Material Zita: Nickel welding Wire, ErNiCrMo-4welding Wire, Hastelloy C276 Welding Wire

MOQ: 15kg

Fomu: MIG (15kgs/spool), TIG (5kgs/bhokisi)

Saizi: dhayamita 0.01mm-8.0mm

Saizi Yakajairika: 0.8MM/1.0MM/1.2MM/1.6MM/2.4MM/3.2MM/3.8MM/4.0MM/5.0MM

Maitiro: Inopindirana neChitupa AWS A5.14 ASME SFA A5.14