Haynes 25 tembiricha yepamusoro uye ngura inodzivirira high end alloy

Haynes 25tembiricha yepamusoro uye ngura inodzivirira high end alloy,

Haynes 25, Haynes 25 mabhaudhi uye nzungu, Haynes 25 brush wire., Haynes 25 fasteners, Haynes 25 flanges, Haynes 25 flat steel, Haynes 25 forgings, Haynes 25 hexagonal bar, Haynes 25 machining zvikamu, Haynes 25 mhete, Haynes 25 round cake, Haynes 25 simbi yakatenderera, Haynes 25 saizi musoro, Haynes 25 ndiro yesimbi, Haynes 25 simbi strip, Haynes 25 mutsetse wakatwasuka, Haynes 25 tee, Haynes 25 welded pombi, Haynes25 waya uye inotsigira welding zvinhu, Haynes25, L-605, R30605, Haynes 25 isina musono chubhu,

Haynes 25bhaudhi, Stud bhaudhi, kaviri bhaudhi, Hexagon bhaudhi

♦ Kukura Kwemusoro: M10-M120

♦ Kureba: zvinoenderana nevatengi kudhirowa kana kufungidzira

♦ Chikumbiro che: Steam turbine generating equipment

♦ Giredhi: Kirasi

Mazita Ekutengesa Anowanikwa: Alloy L605, Co350, HS25, WF-11, ALS1670, UNSR30605, KC20WN,GH5605,Werkstoff 2.4964

Haynes® 25 (L-605) icobalt yakavakirwa alloy inosanganisa kuumbwa kwakanaka uye yakanakisa tembiricha yemhando.Iyo alloy inoshingirira kune oxidation uye carburization kusvika 1900 ° F.Alloy 25 inogona chete kuomeswa zvakanyanya nekushanda kunotonhora.Kutonhora kushanda kuchawedzera simba rekukambaira kusvika 1800 °F uye kudzvanya kuputika simba uo kusvika 1500 °F.Kushungurudza kuchembera pa700 - 1100 °F kunatsiridza kukambaira uye kushushikana kutsemuka kwesimba pazasi pe1300 °F.

Haynes 25 Chemical Kuumbwa

| Alloy | % | Ni | Cr | Co | Mn | Fe | C | Si | S | P | W |

| Haynes 25 | Min. | 9.0 | 19.0 | balance | 1.0 | - | 0.05 | - | - | - | 14.0 |

| Max. | 11.0 | 21.0 | 2.0 | 3.0 | 0.15 | 0.4 | 0.03 | 0.04 | 16.0 |

Haynes 25 Zvinhu Zvenyama

| Density | 9.13 g/cm³ |

| Melting point | 1330-1410 ℃ |

Haynes 25 Mechanical Properties

| Status | Kusimba simba Rm N/mm² | Goho simba Rp 0. 2N/mm² | Elongation Se % | Brinell kuoma HB |

| Solution kurapwa | 960 | 340 | 35 | ≤282 |

Haynes 25 Mitemo uye Zvinotsanangurwa

AMS5759, AMS5537, ASTM F90, AMS 5796

| Bar/Rod | Forgings | Strip/Coil | Sheet/Ndiro | Pipe/Tube |

| AMS5759, ASTM F90 | AMS 5759 | AMS5537 | AMS5537 | GE B50T26A |

Haynes 25 Inowanikwa Zvigadzirwa muSekonic Metals

Haynes 25 bars & Rods

Round bars/Flat bars/Hex bars, Saizi Kubva 8.0mm-320mm, Inoshandiswa kumabhaudhi, mabhaudhi uye zvimwe zvakasara

Haynes 25 welding waya

Supply in welding wire uye spring wire mune coil fomu uye kucheka kureba.

Haynes 25 Forging Ring

Kugadzira Mhete kana gasket, saizi inogona kugadzirwa neyakajeka pamusoro uye nekunyatso kushivirira

Haynes 25 pepa & ndiro

Upamhi hunosvika 1500mm uye kureba kusvika 6000mm, Hukobvu kubva 0.1mm kusvika 100mm.

Haynes 25 isina musono chubhu & Welded pombi

Mayero saizi uye yakasarudzika dimension inogona kugadzirwa nesu nekushivirira kudiki

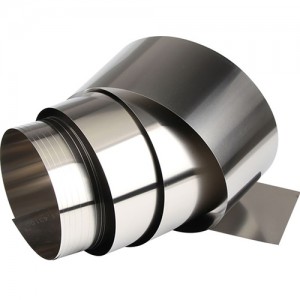

Haynes 25 strip & coil

Yakapfava mamiriro uye yakaoma mamiriro ane AB inopenya nzvimbo, yakafara kusvika 1000mm

Haynes 25 Fasteners

Haynes 25 zvinhu mumhando dzeBolts, zvikururu, flanges uye zvimwe zvinomhanyisa, zvinoenderana nevatengi.

Nei Haynes 25 ?

1. Kutsungirira kwepakati uye simba rinokambaira pasi pe815.

2. Yakanakisa oxidation kuramba pazasi 1090 ℃.

3. Kugadzira kunogutsa, welding uye zvimwe zvigadzirwa zvetekinoroji.

Haynes 25 Munda wekushandisa:

Haynes 25 yakapa basa rakanaka mune dzakawanda jet injini zvikamu.Zvimwe zveizvi zvinosanganisira turbine blades, makamuri ekupisa, zvikamu zvemashure, uye mhete dzeturbine.Iyo alloy yakashandiswawo zvinobudirira mumhando dzakasiyana dzemaindasitiri echoto mashandisirwo anosanganisira choto muffles uye liner munzvimbo dzakaoma munzvimbo dzekupisa tembiricha.

Haynes25, UNSR30605, simba rakanakisisa, kupikisa kwakanaka kweoxidation kusvika ku1800 F (980C), kumira kwakanaka kwemunyu, uye kutaridzika kwakanaka kwekusagadzikana uye kusapfeka. Sekonic Metals Technology Co., Ltd yakazvipira kupa zvigadzirwa zvemhando yepamusoro kuvatengi vedu.Kana uchifarira zvigadzirwa nemasevhisi edu, ndapota taura nesu.Kutarisira mhinduro yako Phone/WhatsApp :0086-15921454807