Haynes25 high temperature resistant alloy

Haynes25 yakakwirira tembiricha inodzivirira alloy,

Haynes25 kuumbwa, L605, performance, R30605,

Mazita Anowanikwa Ekutengeserana: Haynes 25, AlloyL605, Cobalt L605,GH5605, Udimet L605, UNSR30605

Haynes 25(AlloyL605) mhinduro yakasimba yakasimbisa cobalt-chromium-tungsten nickel alloy ine simba repamusoro-tembiricha uye yakanakisa oxidation kuramba kusvika 2000°F(1093°C).Iyo alloy inopawo kumira kwakanaka kune sulfidation uye kuramba kupfeka uye galling.Alloy L-605 inobatsira mukushandisa gasi turbine semhete, mashizha uye zvikamu zvekamuri yekupisa (mashizha machira) uye inogona zvakare kushandiswa mumaindasitiri echoto maficha senge muffles kana liner mune yakanyanya kupisa tembiricha.

Haynes 25(Alloy L605) Chemical Composition

| C | Cr | Ni | Fe | W | Co | Mn | Si | S | P |

| 0.05-0.15 | 19.0-21.0 | 9.0-11.0 | ≦3.0 | 14.0-16.0 | balance | 1.0-2.0 | ≦0.4 | ≦0.03 | ≦0.04 |

Haynes 25(Alloy L605) Zvinhu Zvenyama

| Density (g/cm3) | Melting point (℃) | Kunyanya kupisa simba (J/kg ·℃) | Electric resistivity (Ω·cm) | Thermal conductivity (W/m·℃) |

| 9.27 | 1300-1410 | 385 | 88.6×10E-6 | 9.4 |

Haynes 25(Alloy L605) Mechanical Properties

Representative Tensile Properties, Sheet

| Tembiricha, °F | 70 | 1200 | 1400 | 1600 | 1800 |

| Ultimate Tensile Strength, ksi | 146 | 108 | 93 | 60 | 34 |

| 0.2% Goho Simba, ksi | 69 | 48 | 41 | 36 | 18 |

| Elongation,% | 51 | 60 | 42 | 45 | 32 |

Typical Stress-Kubvarura Simba

| Tembiricha, °F | 1200 | 1400 | 1500 | 1600 | 1700 | 1800 |

| 100 Maawa, ksi | 69 | 36 | 25 | 18 | 12 | 7 |

| 1,000 Maawa, ksi | 57 | 26 | 18 | 12 | 7 | 4 |

Haynes 25(Alloy L605) Mitemo uye Zvinyorwa

AMS 5537, AMS 5796, EN 2.4964,GE B50A460,UNSR30605,Werkstoff 2.4964

| Bar/Rod | Wire/Welding | Strip/Coil | Sheet/Ndiro | Pipe/Tube |

| AMS 5537 | AMS 5796/5797 | AMS 5537 | AMS 5537 | - |

Haynes 25(Alloy L605) Inowanikwa Zvigadzirwa muSekonic Metals

Alloy L605 Mabhari & Tsvimbo

Round bars/Flat bars/Hex bars, Saizi Kubva 8.0mm-320mm, Inoshandiswa kumabhaudhi, mabhaudhi uye zvimwe zvakasara

Alloy L605 welding waya

Supply in welding wire uye spring wire mune coil fomu uye kucheka kureba.

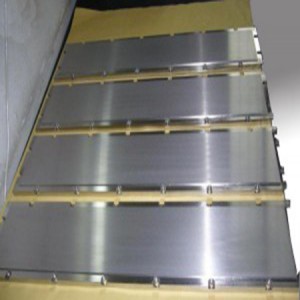

Alloy L605 sheet & plate

Upamhi hunosvika 1500mm uye kureba kusvika 6000mm, Hukobvu kubva 0.1mm kusvika 100mm.

Alloy L605 Gasket / Mhete

Dimension inogona kugadzirwa neyakajeka pamusoro uye kushivirira chaiko.

Alloy L605 strip & coil

Yakapfava mamiriro uye yakaoma mamiriro ane AB inopenya nzvimbo, yakafara kusvika 1000mm

Sei Inconel Haynes 25(Alloy L605) ?

•Yakatanhamara yakakwirira tembiricha simba

•Oxidation inoshingirira kusvika 1800°F

•Galling resistant

•Inopikisa nharaunda dzemugungwa, asidhi uye mvura dzemuviri

Haynes 25(Alloy L605) Nzvimbo yekushandisa:

•Gasi turbine injini zvikamu zvakadai semakamuri ekupisa uye afterburners

•High tembiricha bhora mabhengi uye kubereka marudzi

•Springs

•Mavharuvhu emwoyo

Haynes 25 alloy icobalt-nickel-cr-w alloy ine - yakakwirira tembiricha simba uye -1800 ° F (980 ° C) oxidation nharaunda, kuratidzwa kwenguva refu, uye - vulcanization resistance. Inogona kugadzirwa nekuumbwa nemaitiro echinyakare uye ine akashandiswa kukanda zvidimbu.Zvimwe zvinoyevedza zvinosanganisira kusada kusakara uye kubvaruka pasimbi.Chigadzirwa chiripo fomu: Zvishandiso zvinogadzirwa zviri muchimiro chendiro, mashizha, mitsetse, mabheti, tsvimbo, waya, maelectrode akavharidzirwa, machubhu nemachubhu. : Haynes 25 Alloy yakanzi R30605.Mabhawa, mabhawa, Waya neForgings: AMS 5759 (mabhawa, mhete nefosho), Mashizha, mashiti nemashizha: AMS 5537 (Mashizha, zvidimbu nemashizha) Zvimwe: AMS 5796 (Waya) neAMS 5797 (Coated Welding electrodes)