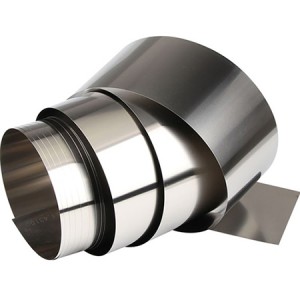

Stainless Simbi PH15-7MO

Mazita Ekutengeserana Anowanikwa:Ph15-7Mo,15-7MoPH,S15700, 07Cr15Ni7Mo2Al,W.Nr 1.4532

15-7M0Ph simbi alloy inogona kumira marudzi ese ekutonhora kuumba uye welding process pasi pemamiriro eaustenite.Zvadaro kuburikidza kupisa kurapwa anogona kuwana

simba gurusa;Pasi pe550 ℃ ine yakanakisa tembiricha yakasimba, yakagadzirirwa kuve nekuoma kukuru kupfuura 17-4 PH.The alloy is martensitic in structure in annealed condition uye inosimbiswazve neashoma tembiricha yekupisa kurapwa iyo inokonzeresa mhangura ine chikamu mune alloy.

| C | Cr | Ni | Mo | Si | Mn | P | S | Al |

| ≤0.09 | 14.0-16.0 | 6.5-7.75 | 2.0-3.0 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.75-1.5 |

| Density (g/cm3) | Electrical resistivity (μΩ·m) |

| 7.8 | 0.8 |

| Condition | pb/N/mm2 | б0.2/N/mm2 | δ5/% | ψ | HRW | |

| Kunaya kuoma | 510 ℃ kuchembera | 1320 | 1210 | 6 | 20 | ≥388 |

| 565℃ kuchembera | 1210 | 1100 | 7 | 25 | ≥375 | |

Steel Steel 15-7Mo Mitemo uye Zvinyorwa

AMS 5659, AMS 5862,ASTM-A564 ,W.Nr./EN 1.4532

Simbi 15-7Mo Inowanikwa Zvigadzirwa muSekonic Metals

Nei Simbi 15-7Mo?

•Inogona kumira marudzi ese ekutonhora kuumba uye welding process pasi pemamiriro e austenite.ipapo kuburikidza nekupisa kurapwa kunogona kuwana yakanyanya

simba, Pasi pe550 ℃ ine yakanakisa tembiricha simba.

•Magetsi welding midziyo: Simbi inogona kutora arc welding, resistance welding uye gasi rakadzivirirwa arc welding, gasi rakadzivirirwa welding ndiyo yakanyanya kunaka.

Welding inowanzoitwa mumidziyo yakasimba mhinduro yekurapa mamiriro, uye haifanire kudziya preheat isati yavekupisa.

Kana welding ichida simba rakawanda, iyo 17-7 ine yakaderera yemukati ye δ- ferrite inosarudzwa zvakanyanya, austenitic Stainless simbi welding waya inogona kushandiswa.

Simbi 15-7Mo Kushandisa ndima:

Inoshandiswa kugadzira avhiyesheni yakatetepa-madziro chimiro zvikamu, marudzi ese emidziyo, mapaipi, chitubu, valve firimu, chikepe shaft,

compressor ndiro, reactor zvikamu, pamwe neakasiyana ezvimiro zvemichina yemakemikari, nezvimwe.