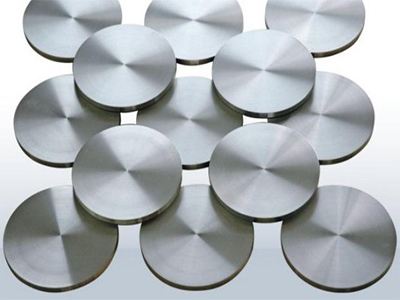

Titanium Disc

Titanium Discinowanzo shandiswa kugadzira kugadzirwa mu titanium flange kana Titanium tubesheet yekupisa midziyo yekupisa.

Sekambani ine makore anopfuura makumi maviri eruzivo rwekugadzira, isu tine nhevedzano yeakaomesesa forging process uye oparesheni bhuku, kusanganisira nhanho dzekudziya, nguva yekudziya uye nguva yekuchengetedza kupisa.Iyo 35MN uye 16MN yekukurumidza yekugadzira muchina yakavimbisa kuwanda kwekugadzira mune yakakodzera tembiricha renji.Uye tekinoroji yekugadzira inogona kushandura chimiro chetitanium disc.Yakavandudza zvakanyanya kunaka kwetitanium disc level.

• Tittanium Disc Materials: Pure Titanium,Grade1, Grade 2, Grade 5, Grade 5, Grade7, Grade9, Grade11, Grade12, Grade 16, Grade23 ect

• Mafomu: Mayero Saizi kana sekutara kwevatengi.

• Dimension: OD: 150 ~ 1500mm, Ukobvu: 35 ~ 250mm, Yakagadzirirwa

• Maitiro:ASTM B265, ASTM B381

• Kuongorora:Muedzo wekuumbwa kwekemikari → Muedzo wezvinhu zvemuviri → Ongororo yeMacroscopic → Kuonekwa kwekukanganisika kwe Ultrasonic → Kuongororwa kunokanganisa chitarisiko

| Titanium Alloys Material Common Name | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Disc Kemikari yakagadzirwa ♦

| Giredhi | Kemikari yakagadzirwa, uremu muzana (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Zvimwe Zvinhu Max.chimwe nechimwe | Zvimwe Zvinhu Max.zvachose | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum DiscZvinhu Zvenyama ♦

| Giredhi | Zvinhu zvemuviri | |||||

| Kusimba simba Min | Goho simba Zvishoma (0.2%, offset) | Elongation mu4D Zvishoma (%) | Kuderedzwa kweNzvimbo Zvishoma (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Titanium Alloy Materials Features: ♦♦♦

•Giredhi 1: Yakachena Titanium, yakaderera simba uye yakakwira ductility.

•Giredhi 2: Iyo yakachena titanium inonyanya kushandiswa.Kubatanidzwa kwakanakisisa kwesimba

•Giredhi 3: Yakakwirira simba Titanium, inoshandiswa kuMatrix-maplateti mugoko uye chubhu yekupisa inotsinhanisa

•Giredhi 5: Iyo yakanyanya kugadzirwa titanium alloy.Simba rakakwirira zvakanyanyisa.kupisa kwakanyanya.

•Giredhi 7: Superior corrosion kuramba mukudzikisa uye oxidizing nharaunda.

•Giredhi 9: Yakanyanya kusimba simba uye ngura kuramba.

•Giredhi 12: Zvirinani kupisa kupisa pane yakachena Titanium.Zvikumbiro seGrade 7 uye Grade 11.

•Giredhi 23: Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy yekuvhiya kuisa kuiswa.