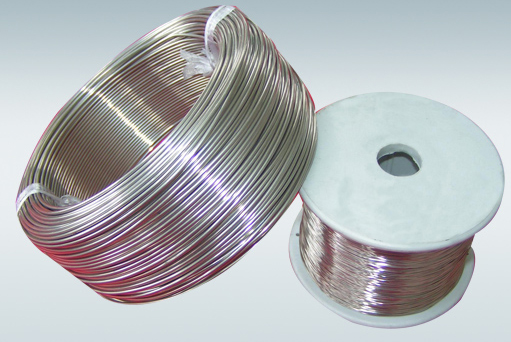

Titanium Wire

Titanium WireTaya yetitanium inowanzo shandiswa kugadzira, mafuremu, kuvhiyiwa implants, kushongedzwa, electroplating hanging fixture.Inoshandiswa mukugadzira spherical titanium powder.

Waya shandisa titanium bar kana Titanium slab tipinde muforoma kuti igadzirise, nekuda kwekudhonza, iyo titanium bar inodzima pasi pekupisa kwepamusoro kana nepaburi reforoma.Chikamu chemuchinjikwa chinoderedzwa, uye urefu hwakawedzerwa.Kutambanudza mumamiriro ekupisa kunobatsira kubvisa kushushikana kwemukati uye kuvandudza plastiki yetitanium waya.Iyo inobudirira inonatsiridza kurongeka kwetambo yetitanium, uye kupedzisa kwepamusoro, iyo inogona kuita zvirinani kuita kwakazara.

• Tittanium Wire Materials: Grade1, Grade 2, Grade 5, Grade 5, Grade7 , Grade9, Grade11 , Grade12 , Grade 16 , Grade23 ect

• Waya Mafomu: Spool muCoil, Cheka kureba / Yakatwasuka

• Diameter: 0.05mm-8.0mm

• Conditions:Solution Yakanamirwa, Kupisa kukunguruka, Kutambanudza

• Pamusoro:Pickling White,Bright polished, Acid Yakashambidzwa, Black oxide

• Maitiro:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 nezvimwe.

| Titanium Alloys Material Common Name | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Wire Chemical Composition ♦

| Giredhi | Kemikari yakagadzirwa, uremu muzana (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Zvimwe Zvinhu Max.chimwe nechimwe | Zvimwe Zvinhu Max.zvachose | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy WireZvinhu Zvenyama ♦

| Giredhi | Zvinhu zvemuviri | |||||

| Kusimba simba Min | Goho simba Zvishoma (0.2%, offset) | Elongation mu4D Zvishoma (%) | Kuderedzwa kweNzvimbo Zvishoma (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Titanium Alloy Materials Features: ♦♦♦

•Giredhi 1: Yakachena Titanium, yakaderera simba uye yakakwira ductility.

•Giredhi 2: Iyo yakachena titanium inonyanya kushandiswa.Kubatanidzwa kwakanakisisa kwesimba

•Giredhi 3: Yakakwirira simba Titanium, inoshandiswa kuMatrix-maplateti mugoko uye chubhu yekupisa inotsinhanisa

•Giredhi 5: Iyo yakanyanya kugadzirwa titanium alloy.Simba rakakwirira zvakanyanyisa.kupisa kwakanyanya.

•Giredhi 9: Yakanyanya kusimba simba uye ngura kuramba.

•Giredhi 12: Zvirinani kupisa kupisa pane yakachena Titanium.Zvikumbiro seGrade 7 uye Grade 11.

•Giredhi 23: Titanium-6Aluminium-4Vanadium yekuvhiya kuisa kuiswa.