Inconel X-750 corrosion uye oxidation kuramba uye yakakwirira simba kunaya kunoomesa alloy.

Inconel X-750 corrosion uye oxidation kuramba uye yakakwirira simba kunaya inoomesa alloy,

,

Mazita Ekutengesa Anowanikwa: Alloy X750, Nickel X750,Nicrofer 7016, Superimphy 750, Haynes X750, Pyromet X750, uye Udimet X750 UNS N07750 W.NR 2.4669

Inconel® X750 is nickel chromium alloy yakaita kunaya kwemvura kuomeswa nekuwedzera kweTitanium nealuminium.Yakashandiswa munzvimbo dzakakwirira dzekupisa dzakaita seQAS turbines, jet engine components, nuclear power plant applications, heat treatment fixtures, maturusi ekugadzira uye extrusion dies.The alloy inopikisa zvakanyanya kumakemikari ekuora uye oxidation, uye ine simba guru rekutsungirira. uye kuderera kwezvinokambaira pamamiriro ekunetseka kwakanyanya kusvika ku1500 ° F (816 ° C) mushure mekurapa kwakakodzera kwekupisa.Inconel X-750 inogona kugadziriswa uchishandisa nzira dzechinyakare dzesimbi-based alloys.Iri simbi inoshanda zvakaoma panguva yekugadzirisa uye ine simba rakakwirira uye "kunamira" kupfuura simbi dzakajairwa. Heavy machining equipment uye maturusi anofanira kushandiswa kuderedza flutter kana kushanda kuoma kwealloy asati acheka chombo.Inconel X-750 Corrosion Resistant Inconel X-750 ine yakanakisa kupikisa chloride ion stress corrosion cracking. Inoratidza inogutsa oxidation kuramba munzvimbo dzakasiyana-siyana oxidizing.Iyo alloy inoratidzira yakafanana corrosion resistance kune alloy 600 mune dzakawanda media.

Inconel X750 Chemical Kuumbwa

| Alloy | % | Ni | Cr | Fe | Nb+Ta | Co | C | Mn | Si | S | Cu | Al | Ti |

| X750 | Min. | 70.0 | 14.0 | 5.0 | 0.7 | 0.4 | 2.25 | ||||||

| Max. | - | 17.0 | 9.0 | 1.2 | 1.0 | 0.08 | 1.0 | 0.5 | 0.01 | 0.5 | 1.0 | 2.75 |

Inconel X750 Zvenyama Zvivakwa

| Density | 8.28 g/cm³ |

| Melting point | 1390-1430 ℃ |

Inconel X750 Typical Mechanical Properties

| Status | Kusimba simba Rm N/mm² | Goho simba Rp 0. 2N/mm² | Elongation Se % | Brinell kuoma HB |

| Solution kurapwa | 1267 | 868 | 25 | ≤400 |

Inconel X750 Miyero uye Matsanangudzo

AMS 5667,AMS 5671,AMS 5698 ,AMS 5699 ,ASTM B637,BS HR 505,GE B14H41,ISO 15156-3 (NACE MR 0175)

| Waya | Sheet | Strip | Rod | Pipe |

| AMS5698 AMS 5699 | AMS5542 | AMS5542 | AMS 5667 AMS 5670AMS 5671 | AMS 5582 |

Inconel X750 Inowanikwa Zvigadzirwa muSekonic Metals

Inconel X 750 Mabhawa & Tsvimbo

Round bars/Flat bars/Hex bars, Saizi Kubva 8.0mm-320mm, Inoshandiswa kumabhaudhi, mabhaudhi uye zvimwe zvakasara

Inconel X 750 welding waya

Supply in welding wire uye spring wire mune coil fomu uye kucheka kureba.

Inconel X-750 Heli-Coil

Helicoil inogona kugadzirwa nesu yakagamuchirwa huwandu hudiki uye nekukurumidza kuburitsa.

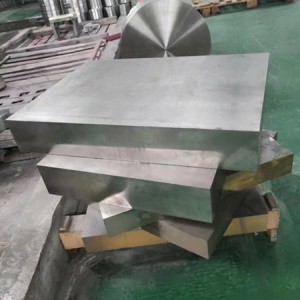

Inconel X 750 pepa & ndiro

Upamhi hunosvika 1500mm uye kureba kusvika 6000mm, Hukobvu kubva 0.1mm kusvika 100mm.

Inconel X750 isina musono chubhu & Welded pombi

Mayero saizi uye yakasarudzika dimension inogona kugadzirwa nesu nekushivirira kudiki

Inconel X 750 Chitubu

Chitubu chine AMS5699 Mayero zvinoenderana nevatengi kudhirowa kana kutsanangurwa

Inconel X750 strip & coil

Yakapfava mamiriro uye yakaoma mamiriro ane AB inopenya nzvimbo, yakafara kusvika 1000mm

Inconel X 750 Fasteners

Alloy X 750 zvinhu mumhando dzeBolts, zvikururu, flanges uye zvimwe zvinomhanyisa, zvinoenderana nevatengi.

Inconel X 750 Tubing Hanger

Inogona kugadzirwa zvinoenderana nevatengi kudhirowa kana smaples nekunyatso kushivirira.

Inconel X-750 Features :

1.Good creep kuputika simba pakupisa kwakanyanya

2.Isina kusimba seNimonic 90

3.Zvakanaka kwazvo pakushisa kwe cryogenic

4.Age yakaoma

5.High tembiricha dynamic applications

Inconel X-750 Nzvimbo yekushandisa:

•Nuclear reactors

•Magetsi emagetsi

•Rocket injini

•Kumanikidza midziyo

•Zvivakwa zvendege

Kambani Yedu Zvigadzirwa Mafomu

Mabhawa & Matanda

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless Tube & Welded Tube

Nickel/ Titanium Alloy machubhu, U-bend / kupisa kwekuchinjana chubhu

Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Sheet & Plates

Hastelloy/Inconel/Incoloy/Cobalt/Tianium

Strip & Foil

Hastelloy/Inconel/ invar/ soft magnetic Alloys ect

High Temperature Springs

Inconel 718/Inconel x750/ Nimonic 80A

Wire & Welding

Cobalt Alloy waya, nickel alloy waya, Tianium Alloy waya

Special Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Mafuta Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Nickel Based Alloys

Welding Materials

Cobalt Based Alloys

Special Stainless Steels

Precision Alloys

Titanium Alloys

Unoda Kudzidza Zvakawanda kana kuwana quote?

Pinda muBata

Implementation standard :UNS, ASTM,AISI, DIN, GB/T14992, mabhureki anoenderana: GB akajairwa mabhureki GH4145, GH145, OCR15NI70TI3AINB, iyo United States label nhamba: INCONEL X-750, NO7750, German label nhamba:2.4105X7, XCR5569, XCR569FE – XCR569,

Sekonic Metals Technology Co. Yakazvipira kune yakakosha alloy tsvakiridzo nekusimudzira, kugadzira, kutengesa kweX750, kuve nechokwadi chemhando yepamusoro nzvimbo yeX750 sheet, strip, bar, forging, annular, waya uye pombi., akasiyana zvirevo, yakagadzika kupihwa, kugamuchirwa consult.